The prototype molds are the tools used to designed prototype parts. There are different types of feasible molds which can be used for designing prototype parts. The Prototype Molds are basically different from the other production molds because these are the types of molds which are not meant to be used for longer period. However, it can be used for a variety of purposes and it has many benefits too. There are typically different variants of this mold which include:

- MUD or Master Unit Die Molds

- Aluminium Mold Tooling

- Steel Mold Tooling

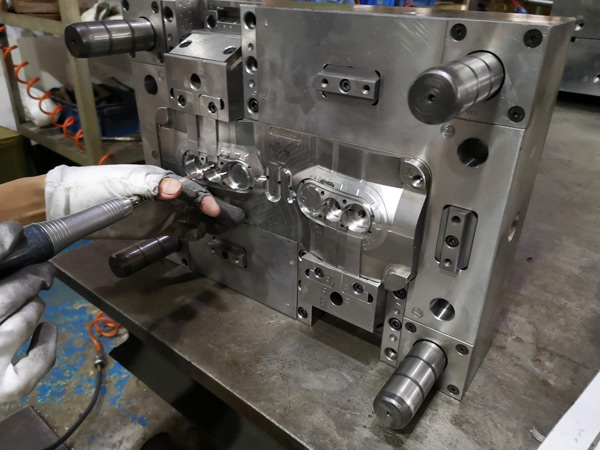

steel mold tooling

What is the Purpose of Prototype Molds?

As mentioned already, the Prototype Molds serve a variety of functions than the final product including the following:

- Inexpensive pre-production mold which can help with troubleshooting and testing the mold prior to the final production

- Shortened lead times to have the version which can be tested or evaluated usually 2-4 weeks

The Prototype Molds are not actually designed to be the final product or version and this means a phased approached is followed so as to build the required mold. Unlike injection mold final version, the Prototype Mold is designed with very inferior materials like the aluminium, non hardened steel or the P20. Since these materials are very less sturdy compared to the final injection mold, you are not able to use them again and again for the final product.

What are the Benefits of Prototype Molds?

If you are not aware how best to meet the final specifications or if you are not sure what the final product to look like, then the Prototype Molds are the best way to facilitate the cost effective and efficient evaluation prior to committing the final mold. There are many companies and industries that are not aware how to move forward with the final product right at the beginning of the process. So, this is when the pre-production injection mold comes to limelight. It can help the businesses to easily determine what works the best and when they need to go back to draw board for correction.

With the Prototype Molds you also have the benefit to make use of low cost materials and it also facilitates quicker process. So, you are no longer under pressure to settle with something that doesn’t satisfy your company’s needs and requirements.

The Different Variants of Prototype Molds!

MUD Molds or Master Unit Die Mold – This is basically the type of mold that includes the standard injection molding frame and this is the design that make use of a variety of inserts so as to define the shape of the internal part. The inserts are designed via CNC machine or the electric discharge machine and this depends on the materials that are being used for designing the inserts. However, in some cases robust materials are used for the inserts, especially when injection molding is used with high molding temperature. Depending upon the materials that are required for the inserts, CNC machines may not be used to make the desired cuts. EDM machines can be used to complete the cuts when CNC machine is not enough for the use. The prime benefit of MUD mold is that it reduces the overall cost and the turnaround time for the prototype revisions.

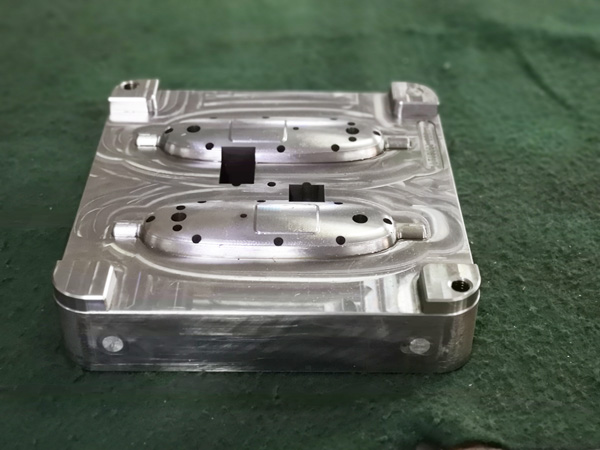

Aluminium Mold Tooling

The final aluminium tooling is the final deliverable for all the projects. The aluminium tools are mainly designed in such a way that it potentially changes can be made during the development processes. In general terms, the aluminium tools are easier to be used compared to the steel tooling and because of its iterative design chances there is very less burdensome. Aluminium is the material that is good conductor of heat and it also cools down very easily and quickly and this is the reason why it is very useful for the injection molding or cyclical process. Because of its quick cooling properties more cycles are offered in the given time frame and this leads to faster production. However, the production is not typically the highest priority when designing the prototyping parts and hence it may or may not be the relevant issue. However, it is very good to understand the fact and it may also help you to make informed decision when it comes to complete scale injection molded manufacturing.

stainless steel mold

Steel Mold Tooling

The steel tools are widely used for the full scale production rather than the prototyping mold. This is the type of the mold which is upgraded version of the MUD and Aluminium tooling. While working with this type of mold the designers usually focus on the production issues instead of the part design. Some of the common concern include gate location, mold flow properties, location and number of vents of the trapped air and also the material properties of particular plastic that is being used.