When you combine the techniques of rapid prototyping and tooling practices that are conventional in style, it is known as bridge mold or rapid tooling. If you want to prepare a mold quickly, then you need to use a bridge mold. While you are using bridge mold, not only time is saved, but money is also saved. Bridge mold can also be termed as the pre-production techniques involved in modeling of tools.

There are two types of rapid tooling:

- Direct rapid tooling

- Indirect rapid tooling

Under direct and indirect rapid tooling, there are a lot of variations. The type of rapid tooling will vary depending on your need.

Methods to use bridge mold

These are the list of steps you need to be following to get the right output using bridge mold.

- The bridge mold or the rapid tooling technique requires one to feed in the design using the CAD program. The CAD software has a lot of tools inbuilt in it that helps you to design the products as per your needs. This is the latest development to the traditional designing.

- Once you have the required CAD software, create the pattern pertaining to which the design of the product must fit into. Before imbibing the pattern into the CAD, make sure to make a rough pattern.

- If you use the bridge mold, then you can refrain yourself from making blunt errors in design.

- Selection of the right prototype plays a vital role in determining the success of the outcome.

- Once the prototype is selected, you can go about making the mold. The same mold can be used for any number of products of the same type.

- To get the products, pour the required metal material into the mold. The other processes that vary from product to product must be followed.

- The duration of drying varies from product to product.

- These are the steps you need to follow one by one to get the right output.

Though the products created using bridge mold have a lesser lifespan, it is the best suited for low-cost projects. One cannot afford to spend a lot on low-cost projects, so bridge mold can be used. It is suggested to rope in a good CAD engineer who can show the 3D model of the product before you finalize.

What are the various advantages of rapid tooling?

- These are the advantages you could obtain when you use rapid tooling.

- The costs can be reduced to lesser than 40-50% than that of the traditional method.

- The mold can be used for varied purposes.

- The soft steel molds are very easy to clarify due to their malleability.

- It is one of the best testing methods if you are going to produce products in huge volumes.

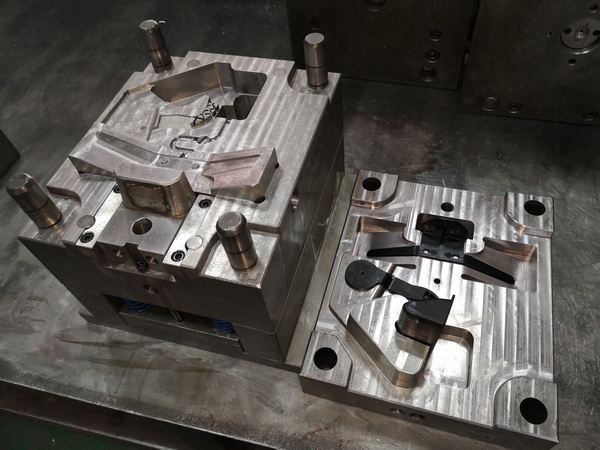

Best metal materials for bridge mold

These are the best metal materials that can be used for a bridge mold.

- Aluminum 7075

- S136H

- NAK80

- P20

These are the things you should know about bridge mold. These play a major role in engineering design.